SDIY is such a painful yet rewarding task. I am a bit of a gluton for punishment in anything that i percieve to be interesting, usually these types of ventures incorporate a level of technical skill that i don't have and have to learn, and somewhere through the process i find something within that i can tailor with my medoicre design skills. SDIY fits into this task perfectly. Initally i had very small idea of how electronics systems worked, today my knowledge is growing larger by the day almost to the point i think i could work as a backup tech at some little electronics shop, not bad for a year or two troubleshooting problems in my rig eh. Electronics has been a big wall to jump however i think it has been beneficial in other fascits of my life, prior to this my logical attention span was minimal, which is not very good when your university degress is effectively in maths haha. So now the inner hack-designer is working on trying to make all these new electornics toys look awesome. So now i have found another task to punish myself with, and this is galvanised etching.

Basically what im going to do is etch an alluminium sheet of specific size. The etchings will be off my synth module faceplate designs. Most etching processes involve an acid that break down any exposed surfaces. Wherever there is contact, as long as you have the appropriate acid for the metal, the acid will pull metal ions from the metal via the chemical interaction. Galv etching works in a similar fassion but with no acid. This is a good thing as i have been using ferric chloride to etch circuit boards and the first time i did it i made myself really sick for about 3 days. That shit it noxious, and not only is it dangerous, it turns everything yellow, and i mean everything. Royal pain in the ass. So with galv etching instead of an acid all we do is breakdown the ions with electronic charge. Easy. You place your plates in a water and sulphide mix, most commonly salt or a sulphide mix with a chemical relationship to your metal. You chuck the annode and cathode from a low powered PSU on either side and the charge of your sollution will have the same chemical breakdown process as with acid however only at the point of contact.

Genius. So im going to give this a go once i have finished my exams.

More info on glav etching here

http://www.greenart.info/galvetch/advan.htm

( i wasnt really specific on the details here so if you are reading thing and are keen, dont use my vague directions goto this source)

The cool thing about this is now i can use exotic metals for my faceplates and be able to have all the decals. Previously i was using rusty steel and it looked great however the only way i could mark it was with a sharpie and it just became to ghetto for me, and that is saying something.

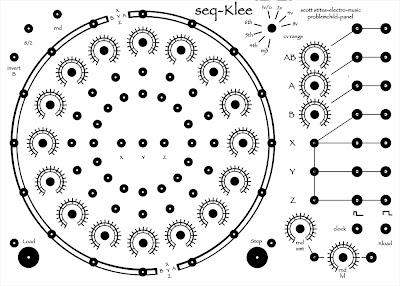

So now while i wait for school to be finished im redesigning all of my faceplates. This is fun. Here are my first 2. Klee Sequencer and Buchla 281c.

More to come.

While re-mounting the Klee onto a new faceplate is going to be a taks and a half, i am glad i got to redesign the panel. After using it over the last few weeks i have realised that a few things on my last panel were a bit skewiff.

Oh yeah 20 more days till i present my thesis. Scary.

Sunday, September 14, 2008

Subscribe to:

Post Comments (Atom)

No comments:

Post a Comment